One common for commercial property owners considering rooftop solar is whether their specific type of roof is suitable for solar installation. So, can solar be installed on any roof or only certain types?

The answer? The rooftop solar industry has come up with innovative and tested solutions for every type of roof type. This blog will look at different types of roofing types and how solar can be installed for each and close with some of the key things to consider for any rooftop solar installation.

The most common types of commercial roofing can be grouped into either flat roofs or pitched roofs, and we’ll look at each in turn.

Flat roofs

Flat roofs are ideal for solar installation as they make installation easy and often can produce the most electricity as modules can usually be oriented in the best directions to maximize solar production. Additionally, for many flatroofs that are below 60ft it is possible to install solar arrays that are completely ballasted without any roof penetrations.

The support structure for flatroof solar installations, or “racking,” is modular. The key variables to consider here are whether the racking faces in one orientation (south if possible) or two (generally east and west) and the tilt for the modules which is generally either 5 or 10 degrees.

Five-degree ballasted racking with a single orientation on a river rock roof

To chose between a single orientation and an east-west orientation the key consideration is the location of your building. You will get the most energy production from facing solar modules towards the south and if your building allows for this then a single orientation is usually best (see first image above). However, if your building does not allow for easy south facing solar orientation then an east-west racking can help maximize production as it usually allows for more modules in a given area.

When deciding between a five- and 10-degree module tilt angle there are a couple things to consider. Five-degree racking is often preferred as it has the smallest space between module rows and therefor allows for larger solar installation. This is because the lower the modules are tilted the less space is required between rows to prevent one row of modules from shading the next row. However, a key benefit of 10-degree racking is that its wider row spacing allows for more convenient access to different parts of the array for maintenance. Additionally, modules tilted at 10 degrees (which are facing south) will produces slightly more efficiently and clean themselves better after rain.

To decide between the different options mentioned above its best to work with a qualified solar installer to assess both your rooftop, building orientation and electricity usage to decide which are best for you.

Out of the standard flatroof materials listed above all are compatible with solar installation, with TPO having the edge for ease of installation and potential for additional production when using bifacial panels (more on this in another blog!). To maintain the roofing warranty a solar contractor will need to put to a small piece of the exact roofing material your building uses called a “slip-sheet” under the solar racking to protect your roofing membrane.

Read Also:

Five-degree ballasted racking with an east-west orientation on a TPO roof

Pitched roofs

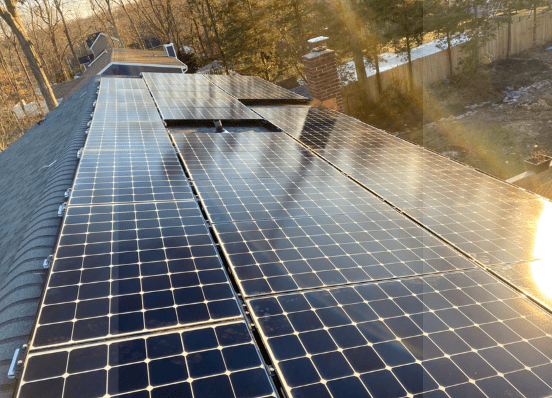

Pitched roofs are also prime candidates for commercial solar installations and are often what people are most familiar with from seeing residential solar installs. The most common pitched roof types are either asphalt shingle or metal roofs.

For asphalt shingle roofs penetrations are generally required and there are several different approaches to flashing these penetrations to ensure that the installation is watertight, and a roof’s warranty is preserved. Some approaches required the removal of shingles around each solar attachment point and the installation of a new piece of metal flashing. However, the approach favored here at Aurora Energy is to use a flexible butyl tape flashing that allows for installation directly on-top of the existing asphalt shingles. This is less invasive and preserves the seal of already installed shingles.

Module support installed on-top of asphalt shingle

Completed asphalt shingle installation

As can be seen in the pictures above pitched roof solar installations generally follow the existing roofing slope of a pitched roof. For this reason, pitched roof faces that are orientated toward the north are not productive and not suitable for solar installation.

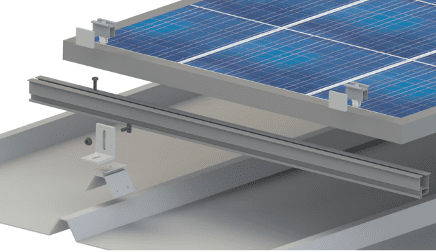

For metal roofs the two most common types are standing seam metal roofs or trapezoidal metal roofs. Both are eligible for solar installation with the key difference being how solar is attached.

With standing seam metal roofs, no penetrations are required. Rather, the solar can be attached to the roof using specially made standing seam clamps that tighten directly onto the existing roof seams.

Standing seam clamp supporting solar rail and modules

With trapezoidal roofs it is necessary to penetrate the roof to install solar. Usually this down using a special “saddle” clamp that fits over the raised trapezoidal roof seam and are screwed down into the metal sheet and then sealed.

Trapezoidal roof racking with saddle clamp

Key considerations

Now that we have reviewed how solar can be installed on some of the most common roofing types and some key design variables lets close with some important things to consider before installing solar on any roof type.

- Roof warranty

There are two types of roof warranties. The first is the installation warranty from the roofer who installed your roof. These generally range from 1-5 years. The second is the overall roofing warranty from the manufacturer of the roofing material that you installed, and these can be for up to 30 years.

If your roof is still covered by either of these warranties, it is important to let your solar installer know. Installing solar, even with mechanical attachments, should not void your existing warranty. However, your solar installer will need to coordinate with your roofer and/or roofing manufacturer to make sure that they are informed.

- Structural strength

Before solar installation on any roof, it is required that a certified structural engineer confirms that your roof can support the added load. Depending on the type of roof and racking, solar puts and average of 2-6 pounds per square foot of additional load on roofs. Usually this is within the existing design parameters of a given roof, but a structural certification is required to make this determination.

- Penetrations

As mentioned above there are some types of solar installations such as those on lower flat roofs and standing seam roofs that do not required roof penetration. However, for tall buildings with flat roofs, asphalt shingle roofs and trapezoidal metal roofs rooftop penetrations are usually required.

The good news is that roof penetrations for solar installation do not need to be a cause for alarm. The import thing is that your solar contractor works with a professional roofer to seal each solar attachment. These additional attachments are similar to the many other types of attachments that are required for rooftop equipment, vents and safety devices and are very prevalent on all rooftops. Attachments sealed by a professional roofer will come with a installation warranty and also should not void any existing roof warranties as long as coordinated with the original roofer and/or manufacturer.